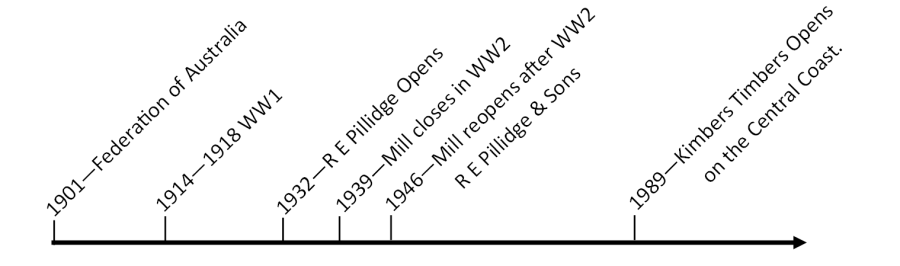

The Pillidge Family has been in the timber industry since 1932. R E Pillidge began with a fire wood block mill and then began selling small sections from the better quality log. The mill closed down in 1939 with workers moving to essential industries to assist with the war effort. The Mill reopened in 1946 after the war with a single breaking down saw in the middle of a paddock and a scavenger class logging license. From there the mill grew becoming R E Pillidge and Sons then employing three generations of the Pillidge Family. In 1989 Stephen Pillidge opened his own timber yard on the central coast naming it Kimbers Timbers after his two children Kimberly and Timothy. We are now a fourth generation timber yard with decades of experience and understanding. So come and meet our team and keep the story alive.

R. E PILLIDGE & SONS SAW MILL

The family saw mill circa 1970. The old sawmill with the breaking down saw (far right), the number 2 saw (right) and the sawdust bin on the left.

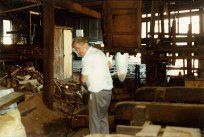

BREAKING DOWN SAW

Don Pillidge resetting the barrow on the breaking down saw. The barrow rolled the full log under the main saw to 'break it down' to manageable sections which then went to the number 2 saw for sizing.

GRADING BENCH

Once the log was broken down the timber was shuttled across the grading bench to the number 2 saw. Here any faults or stress bows were noted ready for final ripping on the number 2 saw.